Double Isolation & Bleed Ball Valve Side Entry

Features:

1. Cast Type with 2 Pcs Split Body Deisgn or Forged Type with 3 PCS

Body Design,

Cast Material: WCB, CF8, CF8M, CF8C, Duplex Stainless Steel, etc.

Forged Material: A105, F304, F316, F317, F347, F11, F51, F59, ETC.

Other Materials available upon Request, available in Various Trim

and Seat (Resilient and Metal) Materials To Suit Different Service

Conditions.

2. Available Operation:

Normal Handle or Lockable Handle Operated,

Gear Operated,

Pneuamtic Operated,

Electric Operated or Hydraulic Operated.

2. Available Pressure Rating:

CL150, CL300, CL600, CL900, CL1500, CL2500

3. Available Size Ranges: 1/2" - 18"

4. Application Standards

Design Standard: API 6D

Flange Dimension to ANSI B16.5

Face to Face Dimension to ANSI B16.10

Pre-temp. Rating of Ball Valve to ASME B16.34

Wall Thickness to ASME B16.34

Fire Safe of Ball Valve Design to API 6FA/API 607

Inspect & Test: API 6D / API598

Valve Marking of Ball Valve: MSS- SP-25

To MR-01-75 On Request

Description

Three pieces body. Valve is designed in accordance with the

requirements of API 6D for pipeline service. Anti-static and anti

blow-out stem design. Seat design gives perfect tighness and is

available as either self-relieving type or double piston effect

type. Disign minimizes friction leading to low operating torque.

Available as double block and bleed execution,which allows for

venting and draining of ling fluid from the body cavity. Avaiable

Full and Reduced bore. Ball valves firesafe tested according to BS

EN 12266-2,API 6FA and API 607. Electric,pneumatic and hydravlic

actuators are available on customer's requirement.

General Introduction

Trunnion mounted ball valves are designed in accordance with API 6D

for classes ASME Class 150, 300, 600, 900, 1500, and 2500.Tow-piece

split body cast steel and Three-piece forged steel side entry

design bolted connections between body and closure, trunnion bolted

connection, body thickness comply with ANSI B16.34.Seat ring is

floating type, spring loaded to assure the contact with ball in

order to provide an effective tight seal even at low differential

pressure between cavity and downstream closure.Standard design is

soft seated. A different soft seat materials are available based on

the customer working condition.Available in Full and Reduced

Bore.Electrical, pneumatic and hydraulic actuators are available

based on customer requirement.Body Joint Construction

Three pieces body end entry design, graphite ring or o-ring viton

(or request) seal ensure absolute seal integrity. The bolted body

designs include a tight tolerance overlapping metal fit between the

body and the adapter to minimize any possibility of movement due to

pipeline stress. High temperature spiral wound stainless steel/

grafoil filled gasket is used for absolute seal.

Body and adaptors are dimensioned for metal contact to ensure

correct gasket crush.

| Ball Valve Type | Design and Manufacture | Face to Face/End to End | Flange Dimensions | Pressure Temperature Rating | Inspection and Test |

| Split Flange ball valve | BS5351 | ANSI B16.10 | ANSI B16.5 | ANSI B16.34 | API6D |

| Fixed flange ball valve | API6D/API608 | API6D | ANSI B16.47 | ANSI B16.34 | API598 |

Main Material

| Body material | Trim material | Seal material | Gasket/Packing |

| WCB/LCB/CF8/CF8M/CF3/CF3M,ETC. | SS410, SS420, SS304, SS316,ETC | PTFE, RPTFE, PEEK, PPL, ETC. | GRAPHITE. PTFE, PPL. ETC.

|

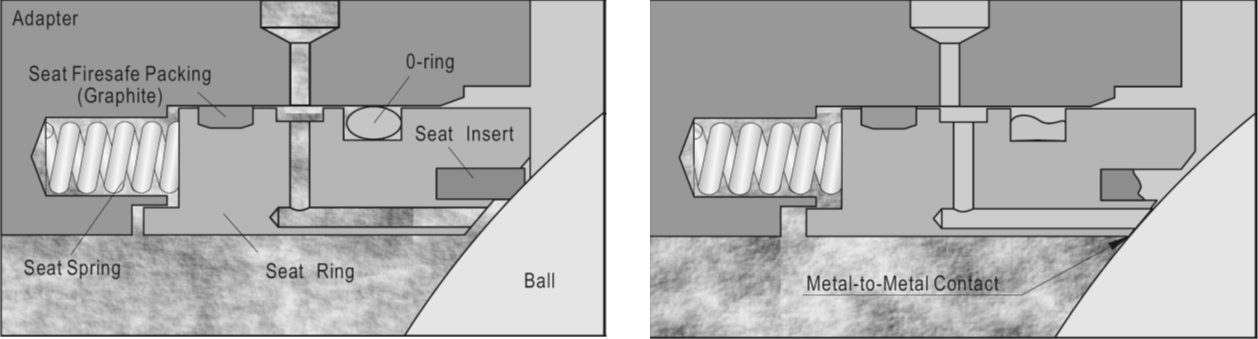

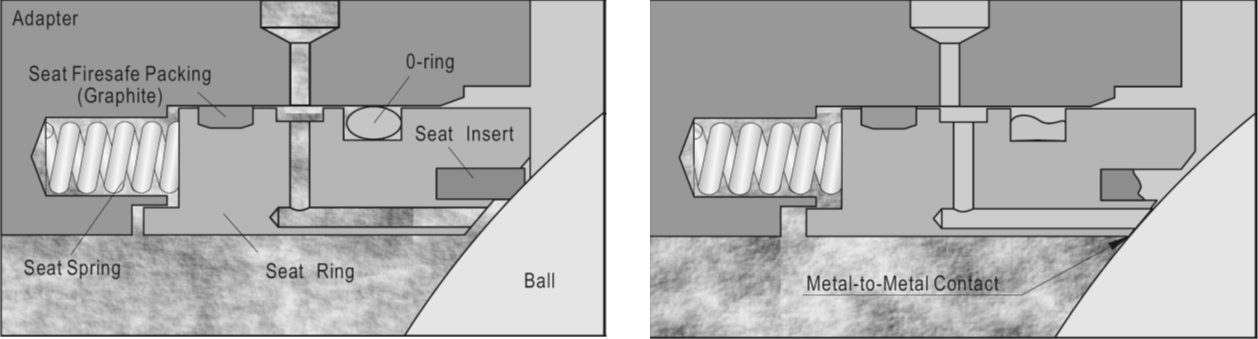

Fire safe design

Ball valves ensures 100% pass of the fire safe test. As Ball valve

applies two sealed design via O-ring seals and metal graphite

spiral wound gasket. When the valve is on fire, non-metallic

materials such as PTFE seat seals, gaskets ,O-ring seals,rubber etc

will be damaged, meanwhile the outer layer of metal graphite spiral

wound gasket provides a secondary seal. When the soft seat is

burned, metal seat will automatically form a metal seal with ball

under the urging of the spring which will effectively control the

internal leakage and external leakage. Valve design fully accords

with API 607, API 6FA, BS 6755, JB / T 6899 and other standards,

Blow-out proof stem:

The stem is made separately from the ball with integral T-type

round shoulder, retained by bland .(other designs are Available on

request)

Anti-static device:

Spring plus graphite type anti-static device are applied between

the ball ,stem, gland Flange and body to keep the electrical

Continuity between all the metallic components . And ensure the

resistance lower than the most severe service requirement.

Grease injection device

For DN150 (NPS 6) & larger the stem and the valve seat are provided

with a sealing grease injection device, For DN125 & smaller, we can

provide the sealing grease injection device according to customer

requirements. When the O-ring is damaged by accident, by injected

sealant sealed to prevent the media through the valve seat ring and

stem leaks.

Sealing Options

Soft seat: Metal to Metal O-Ring seal

Simple structure reliable sealing Applicable to particulate

Reliable sealing low torque meet customers' high

wide application low cost. media conditions sealing reliability and

low torque requirements

DOUBLE BLOCK & BLEED (DBB)

When the ball is in the closed position, each seat seals off the

process medium independently at the same time between the up/down

stream and body cavity, it allows bleeding the trapped cavity

pressure (DBB) through drain and vent valve. The double block and

bleed function make it possible to flush the valve under pressure

and verify that the seat are sealing properly.

DOUBLE ISOLATION & BLEED (DIB)

Double piston effect seat, medium pressure, both upstream and

downstream as well as in the body cavity, creates a resultant

thrust that pushes the seat ring against the ball, valve with

double piston effect seat rings require a cavity pressure relief to

reduce the build-up of over pressure in the body cavity.

The ball is fixed by trunnion and stem for size 4” &smaller.

Trunnion plate support for size 6” & larger